introduction

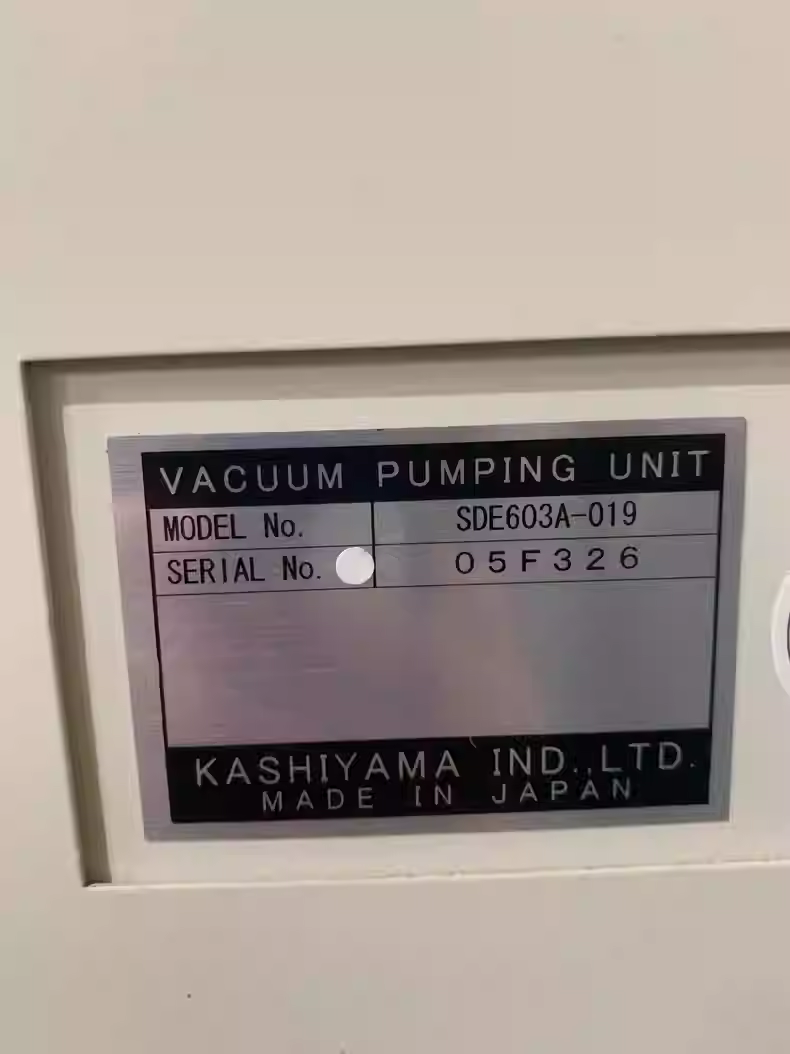

The demand for vacuum environment is increasing in many industrial fields, such as semiconductor manufacturing, chemical production, and scientific research experiments. Dry vacuum pumps have become a key equipment for obtaining vacuum due to their advantages of no oil pollution and low maintenance costs. As a well-known brand, Kashiyama's dry vacuum pumps are quite popular in the market. When purchasing second-hand Kashiyama dry vacuum pumps, it is crucial to clarify the key performance indicators, which are related to whether the equipment can meet actual work needs and operate stably for a long time.

Core performance indicators

pumping speed

Pumping speed refers to the volume of gas that a vacuum pump extracts per unit time at a specific pressure. For second-hand Kashiyama dry vacuum pumps, there is a significant difference in pumping speed among different models. For example, some models in the SDE series can reach a maximum pumping speed of 20000L/min or even higher. In semiconductor manufacturing, quickly establishing a vacuum environment is crucial for improving production efficiency. At this time, a high-speed vacuum pump can significantly shorten the pumping time and meet the strict requirements of the process for vacuum establishment speed. When purchasing, the minimum required pumping speed should be determined based on actual operating conditions to ensure efficient operation of the equipment.

limiting pressure

The ultimate pressure reflects the lowest pressure value that a vacuum pump can achieve, reflecting its ability to create a high vacuum environment. For example, the MUP600E model has a maximum pressure of 0.1Pa (0.001mbar). In optical coating, electron beam welding and other processes that require strict vacuum requirements, low ultimate pressure vacuum pumps are the key to ensuring product quality. Due to different service life and wear and tear levels, the ultimate pressure of second-hand equipment may change, and it needs to be carefully inspected and verified to ensure that it can still meet the high vacuum requirements of the application.

corrosion resistance

In industries such as chemical and pharmaceutical, the gases processed may be corrosive. Some of the vacuum pumps in Kashiyama are made of special materials and coatings, such as stainless steel coating, ceramic coating, etc., to improve corrosion resistance. Taking the treatment of acidic gases (such as HCl and Cl ₂) as an example, corrosion-resistant vacuum pumps can effectively prevent the chamber and rotor from being corroded, extend the service life of equipment, and ensure operational stability. When purchasing second-hand equipment, it is important to understand its past usage environment and whether it has undergone special maintenance or modification for corrosive gases.

energy-saving

As energy costs rise, energy efficiency of equipment becomes increasingly important. Some dry vacuum pumps in Kashima use variable frequency drive (VFD) to regulate speed, which can reduce energy consumption by 30% -50% compared to oil sealed pumps. Under long-term operation, energy-saving vacuum pumps can significantly reduce operating costs. When purchasing second-hand equipment, evaluate its actual energy-saving effect by reviewing equipment operation records, energy consumption data, etc., and select equipment that meets energy-saving requirements.

Stability and reliability

Stable and reliable operation is the foundation for ensuring production continuity. Kashiyama has rich experience in vacuum technology, and some products adopt durable vertical screw structures and other designs, which have good resistance to sediment. However, the stability of second-hand equipment is affected by factors such as usage duration and maintenance status. When purchasing, it is necessary to check whether the equipment has frequent fault maintenance records, understand the wear and tear of its core components, and if necessary, conduct trial operation tests to ensure that the equipment can operate stably for a long time.

conclusion

When purchasing second-hand Kashiyama dry vacuum pumps, the five core performance indicators of pumping speed, ultimate pressure, corrosion resistance, energy efficiency, stability, and reliability are indispensable. By comprehensively considering these indicators and combining them with practical application needs, we can select equipment with high cost-effectiveness that can meet production or scientific research requirements, providing a solid guarantee for the smooth progress of subsequent work.

Haixiang Technology is deeply rooted in the semiconductor industry, focusing on providing cost-effective second-hand semiconductor equipment and supporting services to global customers. Relying on a global procurement network and a senior technical team, we provide long-term and stable supply of precision optical instruments such as wafer appearance inspection equipment, diffusion furnaces, wafer cleaning machines, industrial control computers (industrial computers), and high-end microscopes, covering the needs of multiple stages from the front to the back of semiconductor manufacturing. As practitioners of resource circular economy, we are committed to extending the life cycle of precision instruments through equipment regeneration technology, reducing costs and increasing efficiency for enterprises. Choose Haixiang Technology to make every collaboration a starting point for value regeneration!