Source: official account: comprehensive research on optics and semiconductors

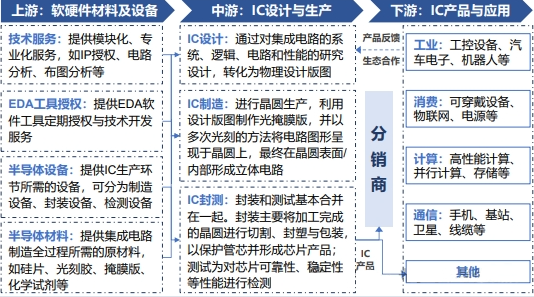

Semiconductor industry chain

The upstream of the semiconductor industry chain is software and hardware materials and equipment, the midstream is the design and production of integrated circuits, and the downstream is the application of end products. The midstream of the semiconductor industry chain includes three major links: design, manufacturing, and packaging and testing. Sealing and testing is the last link in the midstream of the industrial chain. After sealing and testing, the chip is delivered to the chip design factory and then sold to downstream terminal product application enterprises.

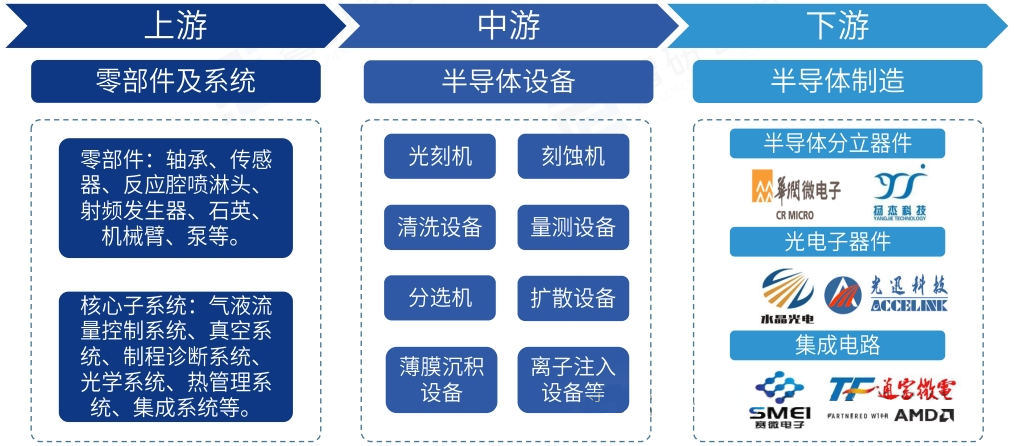

From the perspective of the semiconductor equipment industry chain, the upstream of the semiconductor equipment industry chain mainly consists of components and systems. Components mainly include bearings, sensors, reaction chamber spray heads, RF generators, quartz, robotic arms, pumps, etc; The core subsystems mainly include gas-liquid flow control system, vacuum system, process diagnostic system, optical system, thermal management system, integrated system, etc. The midstream of the industrial chain mainly consists of semiconductor equipment, including lithography machines, etching machines, cleaning equipment, measuring equipment, sorting machines, etc. The downstream of the industrial chain is mainly semiconductor manufacturing, with enterprises including China Resources Microelectronics, Silan Microelectronics, Tongfu Microelectronics, Crystal Optoelectronics, etc.

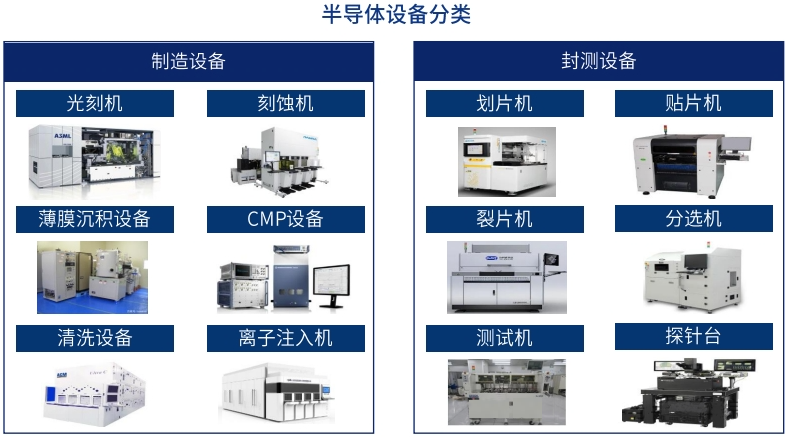

Semiconductor Equipment

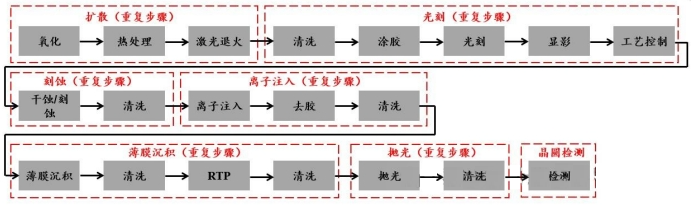

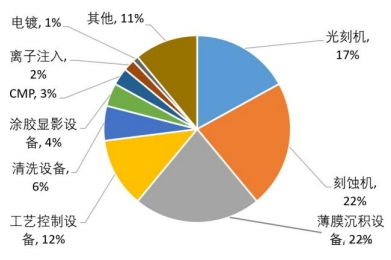

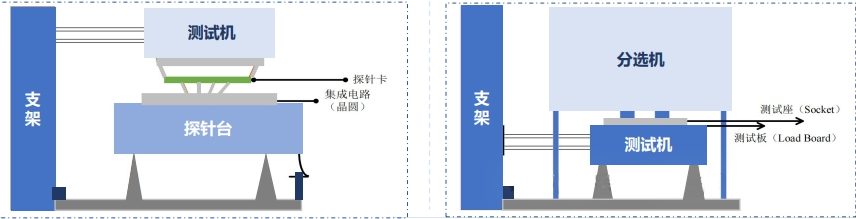

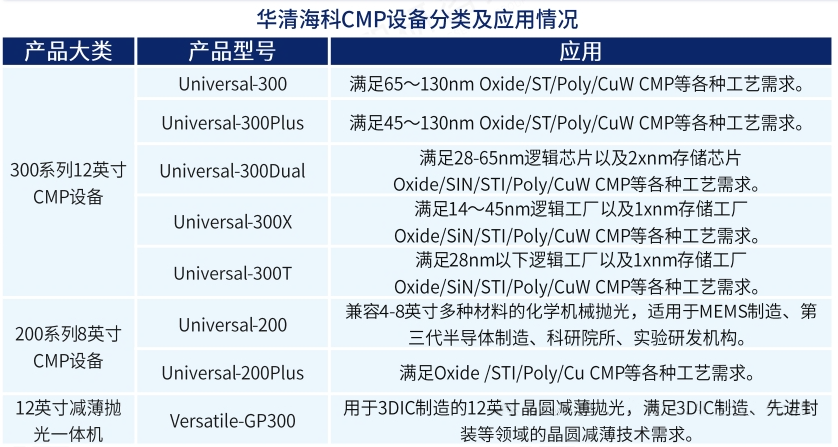

According to the different processes used, semiconductor equipment is usually divided into manufacturing equipment (front-end equipment) and packaging and testing equipment (back-end equipment). The front-end equipment mainly includes lithography machines, etching machines, thin film deposition equipment, CMP equipment, cleaning equipment, ion implantation equipment, heat treatment equipment, etc. The back-end equipment is mainly divided into packaging equipment and testing equipment. Packaging equipment mainly includes cutting machines, surface mount machines, slicing machines, wire bonding machines, cutting and forming machines, etc. Testing equipment mainly includes sorting machines, testing machines, probe stations, etc.

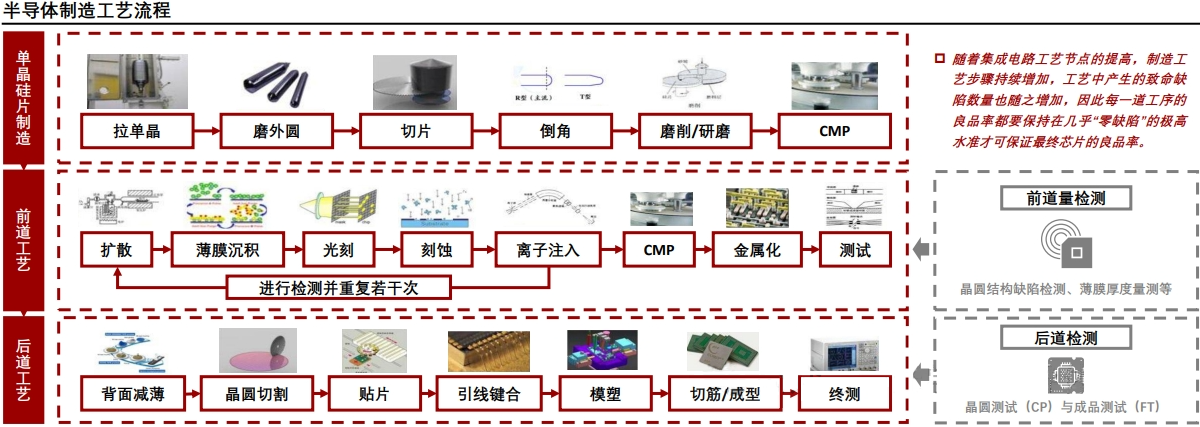

Previous wafer manufacturing process:

Proportion of semiconductor equipment value:

Semiconductor packaging and testing

Encapsulation testing is the abbreviation of encapsulation testing, which includes two stages: encapsulation and testing. Among them, packaging refers to the process of cutting and wire bonding wafers after production and processing, and processing them into finished chips, while testing refers to the use of professional equipment to test the functionality and performance of products.

Packaging: refers to the process of placing, fixing, and sealing chips using specific materials and technology, and connecting the contacts on the chip to the packaging shell. It can protect the performance of the chip and achieve external extension of the internal functions of the chip. The basic packaging process includes wafer thinning, wafer cutting, die attach, solder bonding, encapsulation, post curing, testing, marking (electroplating, bending, laser printing), packaging, warehouse inspection, shipping, and other processes.

Semiconductor packaging process flowchart:

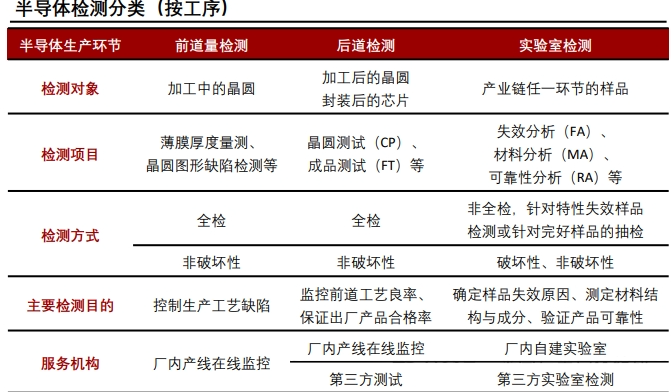

Testing: refers to testing the performance and functionality of chip products, and selecting products that do not meet the requirements for functionality and performance. Testing is mainly divided into chip probing before packaging and final testing after packaging. Testing plays a crucial role in ensuring chip yield, controlling costs, guiding chip design, and process improvement.

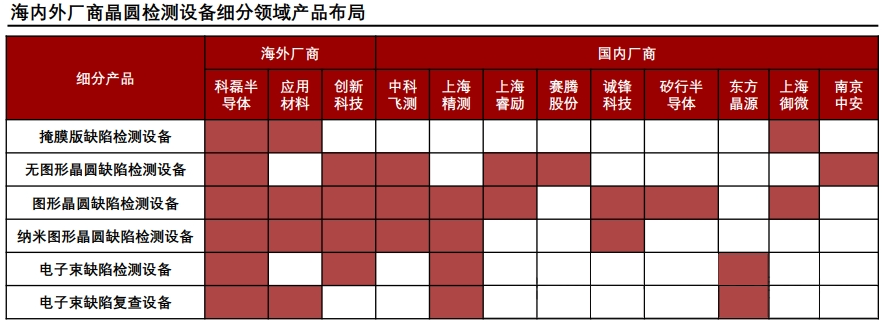

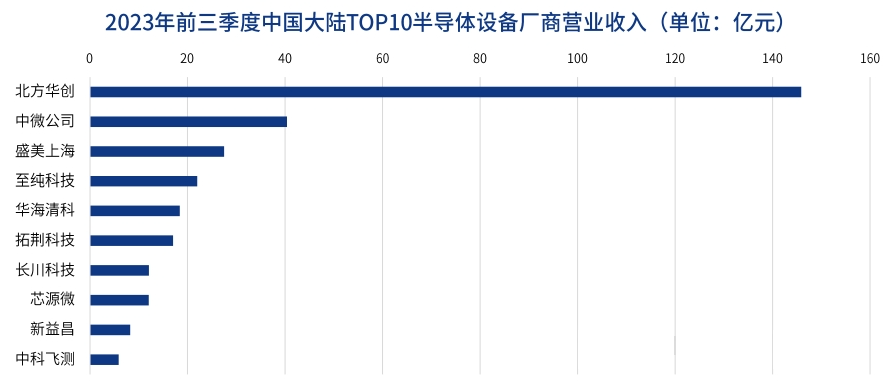

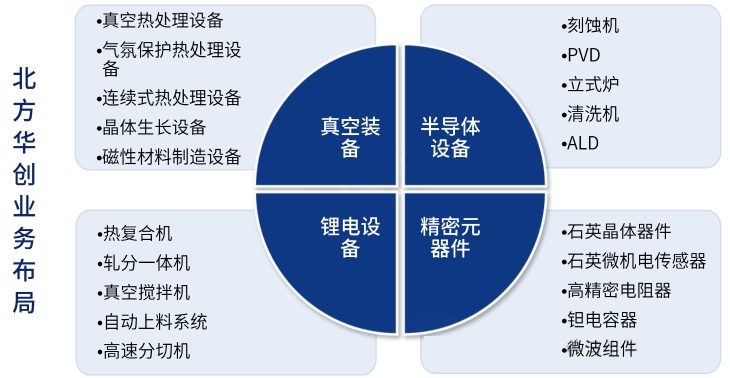

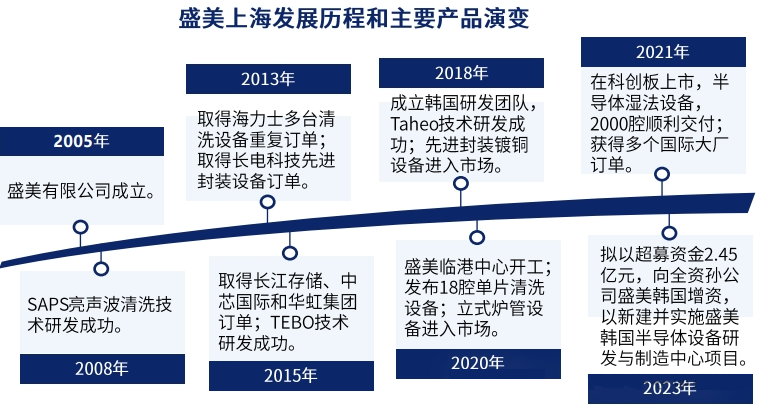

Manufacturer layout

Disclaimer: This article is reproduced or adapted online, and the copyright belongs to the original author. The content of the article is the author's personal opinion. Reproduction is only intended to convey a different viewpoint and does not represent the company's endorsement or support of that viewpoint. If you have any objections, please feel free to contact us.